AFS and ARO Take Major Step to Make Jobs Easier at Retail

With ever-increasing labor challenges, along with continual needs for scale and consistency, the AFS and ARO delicatessen teams are launching a new centralized production initiative this month.

Centralized production facilities, sometimes called commissaries, are commercial-grade cooking and storage companies utilized by food service providers for large-scale product preparation and storage.

“Amber Woodfield, Terri Osborne, James Chambers and I were brainstorming how we might achieve our sales growth with the labor constraints and developed a plan to run satellite commissary shifts for cheeseball production,” said Danerish Root, ARO delicatessen sales manager. “We felt it was a way to serve our team and be able to help all stores.”

Cheeseball sales peak during the fall and winter holidays and stores’ production capabilities cannot always keep up with soaring demand. Cheeseball mix is now shipped in five-gallon tubs making it easy for store teams to simply scoop, package, stock and sell.

As the dream moved forward, ARO collaborated with Ryan Barnes, director of delicatessen, and others from Associated Food Stores and expanded the available products from cheeseballs to salsa, soups, meal kits and more.

“This began as a dream, but the more we talked about it the more we felt we could execute it in a way that greatly benefits retail,” said Ryan.

Having explored these types of solutions before, Ryan, Danerish and others benefitted from using existing systems, so product can be produced in one place and, through cross docks at the Farr West Distribution Center, ship items efficiently to retail.

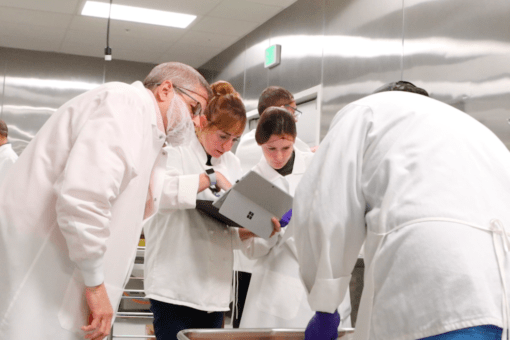

A primary partner in the effort is Tall Hat Foods. Tall Hat Foods, a company based in Lindon, Utah, is owned by Chef Kent Anderson. Anderson is a world-certified master chef and shares that Tall Hat Foods is part food development incubator, part food design studio, part food science laboratory – all infused with lean manufacturer prowess and savvy ingredient procurement.

“Partnerships like the one we have with Tall Hat allow us to have the scale and consistency we want while also allowing store team members to have more time to engage with their customers,” said Ryan. “They are local and we’re very impressed with their commitment to quality, freshness and efficiency.”

“Our first take at this production level was Halloween with production of over 6,000 lbs. of cheeseballs,” said Danerish. “It took over 110 hours between the ARO delicatessen leadership team and some very important vendor partners in Horizon, Rodon Mancini, Provendors and G & G to make this happen.”

Helping stores with the bulk of their production allows AFS and ARO to efficiently promote, offer full variety and alleviate the stress at store level that comes along with the increase of production.

“There were so many teams who helped make this successful,” said Ryan. “The corporate store teams, the finance team, the IT group, accounting, transportation, procurement, the vendor community and many others contributed.”

Special effort was made by Ryan, Danerish, Thomas Brown, Glen Keysaw, Terri Jensen, Darrin Pinkerton, Justin Johnson, Bill Price, Todd Bell, Kiersten Cordingly, Steve Johnson, Rhondda Bagley and others.

“We had hiccups and challenges along the road, but we are ready to dive in big time,” said Ryan. “We are going to be in stock in a way we’ve never been in stock before.”

As part of the centralized production effort, the group established a relationship with a third-party microbial testing facility that helps the team more accurately communicate “use-by” dates and maximize product life.

“Our goal is to alleviate pressure on the stores, to make team members’ jobs easier,” said Danerish. “Our centralized production goes a long way in helping them be more efficient and effective and provides a blueprint for similar efforts in the future for both corporate and member stores.”